Process

|

||||

According to the oilseed speciality and customers' requirements of the final product, we will supply customer a complete solution of the pretreatment line. It includes technical design, equipments manufacture, installation and commissioning. |

||||

|

||||

The YZCL series steaming cooker is used to steam and cook the oilseed flake to meet the technical requirment for next process such as pressing or extraction. This equipment can be also used as softening cooker. After softening, the quality of crude oil and oil output rate can be improved. It's the necessary equipment for pretreatment process in vegetable oil plant. |

||||

|

||||

The ZX series oil press is suitable for complete extracting vegetable oils, such as cotton seed, rapeseed, peanut, sunflower seed, sesame, castor bean, etc. It has characteristic such as high capacity, low power consumption, low cost of running, soft but not powdery cake output and lower oil in cake etc. It's the best choice for large-medium oil plant. |

||||

|

||||

We can supply customer a complete solution of solvent extracting project for various oil materials. It adopts continuity technology, including solvent extraction system, wet meal toasting and desolventing system, miscella evaporation system, solvent recovery system and solvent recovery from vent gas. |

||||

|

||||

The YJCH-IV loop type extractor is an advanced equipment which has been improved and perfected for almost 20 years, nowadays it's well accepted in oils&fats industry. It's capacity is 30~2000t/d. |

||||

|

||||

The desolventizer can separate the solvent from the wet meal. It is suitable for many kinds of materials and different kinds of technologies of extraction process. During the last 20 years, we have constantly practised and improved YDT series desolventizer, now we have YDT, YDTD, YDTDC complete series products. |

||||

|

||||

According to the oil speciality and the grade of product oil, we will supply customer a complete solution. It includes technical design, equipments manufacture, installation and commissioning. According to customers' requirements, customer can choose the suitable technical processes: |

||||

|

||||

With single-axis, multiple-agitator blade and multi-layers, the YTCT series bleaching tower has the innovative structure and excellent technical performance. It is suitable for the bleaching section of continuous refining process and can process raw materials from 50 to 600 ton per day. |

||||

|

||||

The filter is used in fine filtration of liquid materials in many industries. It does not need filter cloth or filter paper so the operation cost can be reduced to a low level. It adopts fully hermetic filtration operation without pollution. The valve can discharge the residue automatically, which greatly reduced the worker's labor and realized automatic and continuous operation. |

||||

|

||||

|

||||

|

||||

| Top | ||||||||||||||||||||||

|

This production line is designed specially for processing the oil bearing materials such as: thorn seed, almond, walnut, wheat germ, sesame seed, and evening primrose. The final product are special type oil and special degreased power. Adoptting the absolute physical refining and bleaching technologies, the activated ingredient can be kept farthest in the oil, upon that the product oil has a characteristic efficacy for nutrition and health. By the WL series air-vortex milling machine, the special degreased power can be produced at the size of 5-300um. After mixing the powder with the additive and other ingredients, we also can get the micro-capsule products through spraying and drying processing.

|

|||||||||||||||||||||

|

||||||||||||||||||||||

|

||||||||||||||||||||||

|

||||||||||||||||||||||

|

||||

|

||||

|

||||

| Top | ||||

The biodiesel can be produced from the following stuff: |

||||

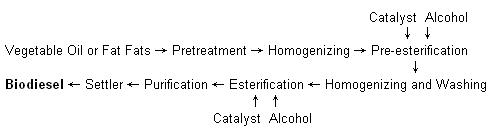

Technical Flow Chart:  |

Main Equipments: |

|||

|

||||